An innovative CO2 capture system:

Based on an aqueous, high pressure process, the patented Pi-CO2 process

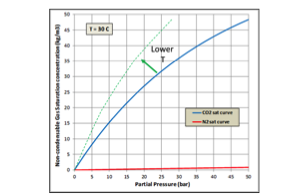

- Uses the Hydrostatic Pressure of a Water Column to Increase the Solubility of CO2 and the differential solubilities of the N2 and CO2 to separate the gases.

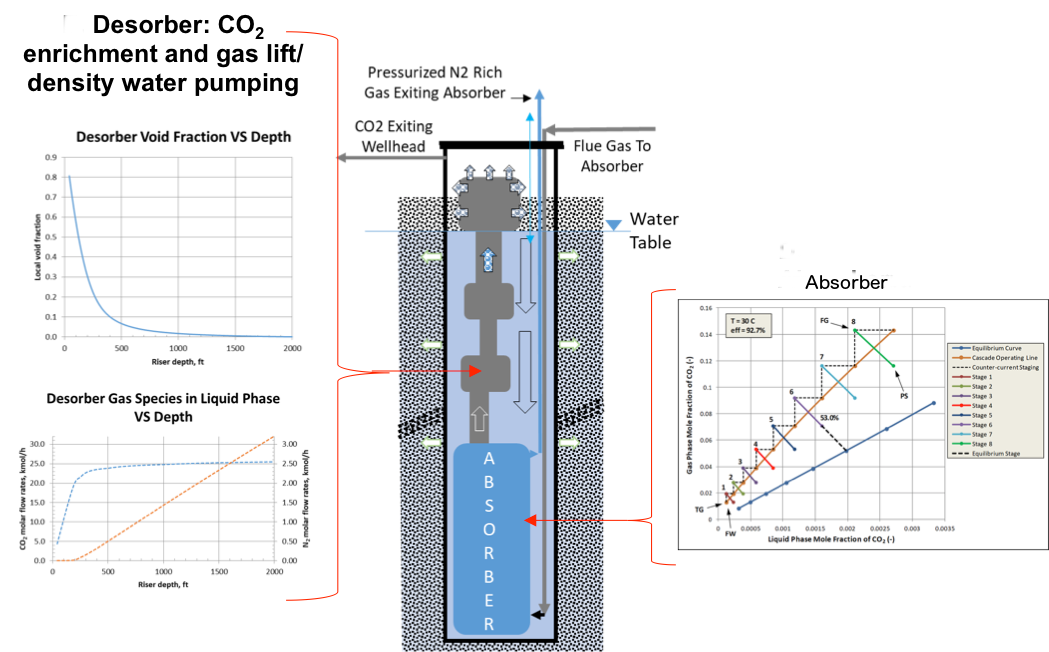

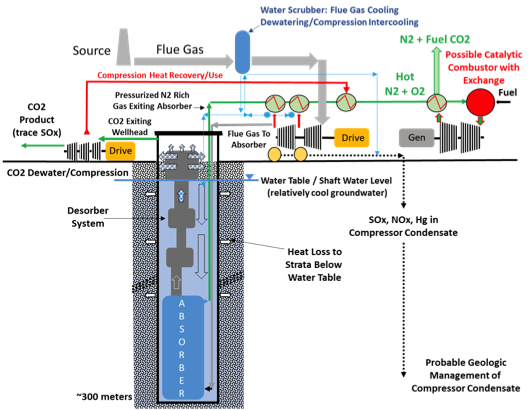

- Simple System – CO2 mass-transfer is maximized in a specialized absorber/desorber, pressure swing supports CO2 enrichment and water circulation

- Low Risk – No Specialty Materials, No Moving Parts Subsurface, ease in Testing & Scaling.

Solubility of gases in H2O

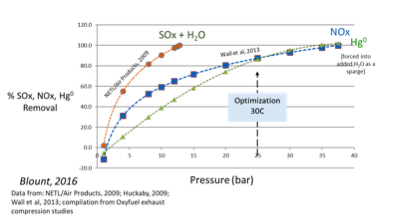

H2O, SOx, NOx, Hg removal during compression

Energy recovery

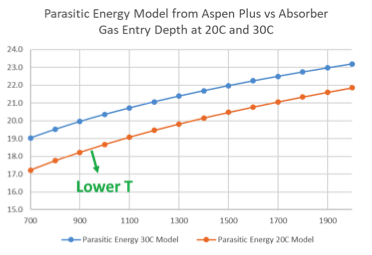

- Capture = ~0.20 MWe /metric ton CO2

- Capture + Product Compression = ~0.25 MWe /metric ton CO2

- With internal combustion of fuel with residual O2 = ~0.10 MWe /metric ton CO2

(Coal fired power plant setting)

Innovations:

- Solubility difference between CO2 and N2 in H2O, water is the physical solvent for capture of CO2;

- H2O, SOx, NOx, Hg removal during compression, no pretreatment is required;

- Energy recovery from N2 rich stream combined with compression heat and internal combustion using residual O2;

- Down-flow counter-current cascading absorber (over 90% capture with 8 stages);

- Desorber with CO2 enrichment and gas lift/density pumping.

- Lower cost and energy demand compared to other technologies: no pretreatment of flue gas, no expensive chemicals, no chemical degradation waste.